Tapping and drilling are two of the basic skills you need to learn when you’re doing DIY projects.

It’s a useful one to learn, especially if you’re planning to fix or make something on your own that needs screws, bolts, and metals.

To start, tapping and drilling are two different things. But, these two are essential to fasten one part to the other. Here are the things you need to know first.

- Have a complete and essential set of tools. Just like making any project, you have to have the right tools or objects in order to accomplish the task. As in the case of drilling and tapping, you will be needing:

- Tap guides. This tool is responsible for ensuring that the threads inside the hole are straight, which is necessary to make the insertion of screws and bolts smooth.

- Oil: It acts as a lubricant and primarily functions as a smoothening agent.

- Center drill. It is a tool that is made of metal that is capable of creating a 60-degree countersink to ensure accurate support of the force to be created by a lathe.

- Pecking: It is the process by which you create a drill through phases instead of a full-scale depth. This prevents the bits or parts of the workpiece from being intact and avoids damage.

- The right amount of force: As in any delicate task, the right of force, especially when tapping and drilling, is a must. Otherwise, the whole workpiece would be a ruin.

So, how do you properly tap and drill holes? We’ll discuss that process here.

1. The drilling part.

Ideally, the hole should be smaller compared to the diameter of the bolt. This ensures that the bolt placed is intact and not loose and that there is enough grip. It would be best if you refer to a size chart for the appropriate drill size respective to the diameter of your bolt.

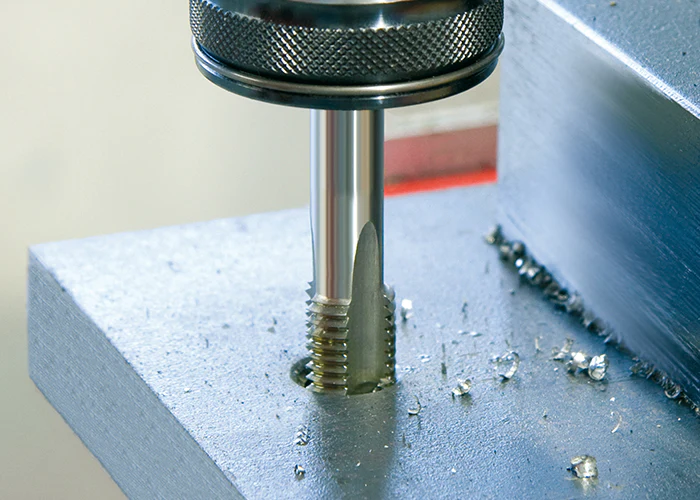

2. The tapping of the hole.

Tapping the hole is basically creating a thread or some sort of harmonious pattern inside to ensure that the fasteners, such as the bolts, can go through.

To begin, get your tapper and rotate clockwise into the material until you feel friction or a counterforce from the threads into the material. Repeat the steps and remember that for every clockwise motion, make a half counterclockwise, too, so that the chips made will be scraped off from the insides and the space is cleared to resume the cutting of the tap.

3. The cleansing and testing of the hole.

Remove the chips made from tapping, including the oil used. It is advisable that you use compressed air to remove the chips completely.

Once done, get the screw or the bolt that you will be using and try to put it inside. When you feel too much resistance, that means, the tapping and threading aren’t right. So, you need to work again on it until it screws smoothly.

When everything screws right, using a thread-locking fluid like Loctite is also recommended. It’s a supplemental tool to ensure that the screws and bolts are not left loose and adds extra grip inside.

Final Words

Doing a project involving metalwork, screws, and bolts is tough but not impossible. The key here is that you don’t hasten the process of tapping, threading, and drilling. Working too fast without attention to detail will jeopardize your work. Also, it is important that you have patience in doing this, given that you’re on a budget and you’re on your own.

Lastly, make sure to get the right tools and always make sure that you execute precision before performing the task.