Steel reinforcement plays several vital roles in a variety of construction projects. There are skyscrapers, industrial warehouses, commercial shopping centres, airports, sea ports, schools, and a number of other infrastructure projects that will require a certain type of steel reinforcement technique vital to the structure’s successful completion and longevity.

We are going to look at some of those techniques below so you can educate yourself further on the type of steel reinforcement your project may require.

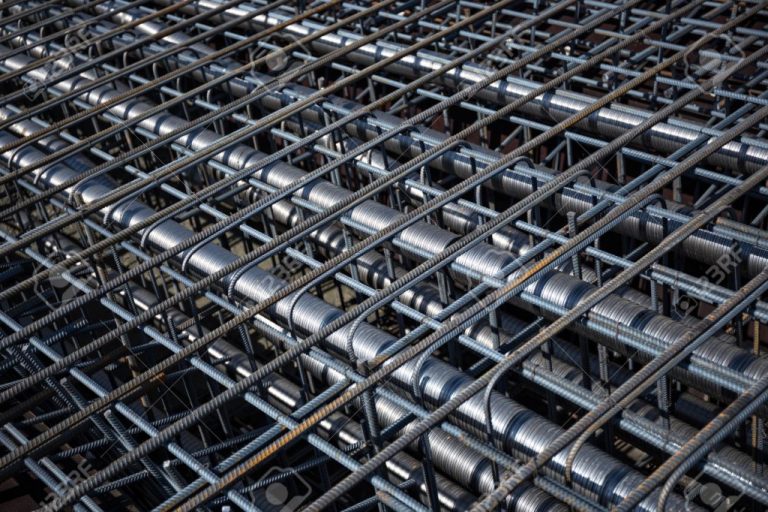

Concrete Mesh Reinforcement

One of the primary benefits of concrete mesh reinforcement is its ability to fortify foundations, ensuring a robust and stable base for your home. By enhancing the structural integrity of your home’s foundation, you can rest assured that your property will withstand the test of time.

- Waterproofing: Waterproofing is another impressive characteristic of concrete reinforcing mesh. The material stabilises the foundation by impeding soil movement, minimising the risk of water infiltration and structural damage. With the added bonus Water Installations: Water installations, including swimming pools, benefit immensely from concrete reinforcing mesh. The mesh strengthens these structures while preventing debris and foreign objects from harming the pool’s internal components.

- Extreme Weather Protection: Concrete reinforcing mesh protects structures against extreme weather conditions. It is especially useful in areas prone to earthquake tremors, or extreme weather changes from hot to cold seasons, The concrete mesh helps protects your structures and reduces the need for repairs and maintenance.

Fiber Reinforced Polymer (FRP)

Fiber Reinforced Polymer (FRP) bars are a relatively new type of reinforcement material used in the construction industry. They are made from a combination of synthetic fibres, such as glass, carbon, or aramid, and a resin matrix, typically polyester or epoxy. This combination of materials results in a lightweight, yet strong and corrosion-resistant reinforcement product.

- Corrosion resistance: Unlike steel, FRP bars do not rust or corrode, making them suitable for use in environments where traditional steel reinforcement may be subject to corrosion, such as marine structures or structures exposed to corrosive chemicals.

- Lightweight: FRP bars are significantly lighter than steel reinforcement bars, making them easier to transport and install. This lightweight property can also result in reduced overall weight for the structure, leading to potential cost savings.

- Non-magnetic: FRP bars do not exhibit magnetic properties, making them suitable for use in structures where electromagnetic interference needs to be minimised, such as hospitals, research facilities, and power plants.

- High tensile strength: FRP bars have a high tensile strength-to-weight ratio, making them an attractive alternative to steel reinforcement in certain applications.

Despite these advantages, FRP bars also have some limitations, such as their sensitivity to UV radiation, lower modulus of elasticity compared to steel, and higher cost. As a result, FRP bars are typically used in specialised applications where their unique properties offer clear benefits over traditional steel reinforcement.

Pre-stressed Concrete

Pre-stressed concrete is a type of reinforced concrete that has been pre-tensioned or post-tensioned to provide additional strength and stability. Pre-stressing involves applying a compressive force to the concrete before it is cast, using high-strength steel cables or bars. This prestressing force counteracts the tensile forces that would otherwise cause the concrete to crack and fail under load.

There are two main types of prestressed concrete:

- Pre-tensioned concrete: In this method, the steel reinforcement is tensioned before the concrete is cast. Once the concrete has hardened, the tension is released, transferring the compressive force to the concrete.

- Post-tensioned concrete: In this method, the steel reinforcement is tensioned after the concrete has hardened. A series of ducts are cast into the concrete, and steel tendons are threaded through these ducts. After the concrete has hardened, the tendons are tensioned, transferring the compressive force to the concrete.

Pre-stressed concrete offers several advantages over traditional reinforced concrete, including increased strength, reduced cracking, and improved durability. It is commonly used in the construction of bridges, parking structures, and other structures where high load-carrying capacity and long spans are required.

Corrosion Protection of Steel Reinforcement

Corrosion of steel reinforcement is a major concern in the construction industry, as it can lead to a reduction in the strength and durability of concrete structures. There are several methods for protecting steel reinforcement from corrosion, including:

- Coating the steel reinforcement: Applying a protective coating to the steel reinforcement, such as epoxy or galvanising, can help to prevent corrosion by acting as a barrier between the steel and the environment.

- Using corrosion-resistant steel: Selecting steel with higher corrosion resistance, such as stainless steel or low alloy steel, can help to reduce the risk of corrosion.

The Ins & Outs of the Role of Steel Reinforcement in Construction

Steel reinforcement plays a vital role in various construction projects, ensuring the successful completion and longevity of structures. Techniques such as concrete mesh reinforcement, fibre-reinforced polymer (FRP) bars, pre-stressed concrete, and corrosion protection measures are essential in achieving a robust and durable infrastructure.

By understanding the specific reinforcement requirements of your project and employing the appropriate techniques, you can ensure the stability and endurance of your construction endeavours. From residential foundations to large-scale infrastructure projects, steel reinforcement remains a crucial element in the world of construction.