Insulation is one of the most overlooked elements in construction. Whether it’s residential or commercial buildings, the elements that shield the walls from the adverse effects of weather provide year-round comfort and sustain the structural integrity of the premises. In this sense, one of the most widespread types of insulation used of late is rigid foam insulation, especially when it comes to roofing and composite deck floors.

What Is Rigid Foam Insulation?

As the name implies, rigid foam is a type of packed foam used in the all-weather thermal sheathing. It’s a cost-effective insulation solution when it comes to reducing heat built-up, particularly in roofs. However, its practicality doesn’t end there. It is often used where moisture or humidity may impede on different structural elements, like basements and floors. The interlocking boards also allow for seamless integration in vertical walls, with minimal gaping. Like most board insulation, it is easily cut to measure and fitted within the building structure. Various materials are used in the different varieties on offer and they all have distinctive insulation properties. To learn more about commercial insulated roofs, you can consult with a roofing contractor or check industry publications and websites for information on the latest products and techniques.

Types of Rigid Foam Insulation

The different mixtures of materials have led to various types of rigid insulation boards. The varying thickness and foam density greatly impact the insulative qualities.

Expanded Polystyrene (EPS)

Expanded polystyrene or beadboard is a lightweight and inexpensive insulation board consisting of rigid, closed-cell thermoplastic polystyrene foam. Internal beads expand when heat is applied. This type of rigid insulation has the lowest thermal resistance, measured as an R-value, as compared to other available options. While adequate for small projects with minimal temperature fluctuations, better heat regulation is achieved with other rigid boards. In addition, when it comes to moisture resistance, it is advised to use coatings or aluminium foil.

Extruded Polystyrene (XPS)

A more costly type of rigid insulation compared to EPS is the so-called blue board or extruded polystyrene. However, this one has better thermal and moisture resistance due to being denser. Extruded polystyrene is a more durable option and doesn’t require coating or film to achieve the same level of insulation.

Mineral Wool

Another product used in thermal insulation is mineral wool. It differs from the polymer-based insulators above in that it is composed of recycled stone dust, making it virtually fireproof and resistant to moisture and humidity. It is also one of the most eco-friendly options on the market.

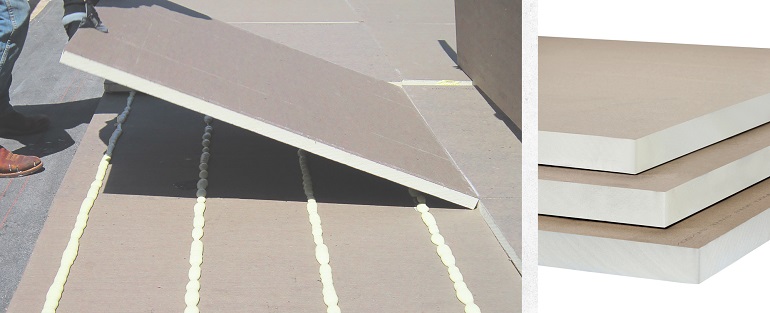

Polyisocyanurate (PIR)

Polyisocyanurate rigid foam is known under several names – Polyiso, ISO or PIR core are regularly used. It is one of the most widespread insulation options used both in residential and commercial roofing applications, due to its higher thermal or R-value than other insulation boards. Its consists of various organic and inorganic substances, generally modified and strengthened polyurethane, in a closed rigid cell structure.

The main elements in this foam insulation are polyol, a fire retardant, a blowing agent, and MDI or methylene diphenyl diisocyanate. A large amount of the materials are recycled and eco-friendly, meaning there’s less harm during installation and no toxic materials are released into the atmosphere.

Facer materials in polysio boards add strength and stability to the foam core. Materials like coated or laminated aluminium and coated or reinforced glass increase the overall thermal properties of the core while also adding moisture resistance or funnelling. This is particularly useful in roof insulation, but also base layers, cover boards and below-grade applications.

Compared to other rigid insulated boards, ISO has far better thermal insulation for the same area due to higher density. Board R-value is further increased with width, providing a good solution for colder climates. Board widths range from a relatively thin 25mm to 150mm. Several widths within that range are also sold and in standard heights and lengths of 2400mm by 1200mm respectively.

Most Iso boards are sold in packaged units of three or more, depending on their width and application. Popular brands in the UK include Ecotherm, Quinn and Kingspan, and the Kingspan TP10 board is ideal for general slanted roofing insulation. To insulate flat roofs with bitumen bases, look for the Kingspan TR24 range of polyiso thermal insulation boards.

Benefits of Polyiso Rigid Foam Insulation

Polysio or PIR rigid insulation has several benefits over other insulated boards. It offers the highest thermal efficiency of all the polymer-based variants mentioned here. It is stable and rigid, won’t deform for the service life of the structure or cause loss of insulation. It retains its physical and thermal properties when exposed to temperature extremes, within the range of -75ºC to +125ºC. Because of this, it is extremely fireproof, with the core retaining stability even when directly exposed to fire. Polyiso or PIR insulation has a minimal environmental impact and was developed as an alternative to insulators with high CFC content responsible for ozone depletion.

In terms or preparation and installation, it is easily formed with a utility knife, with boards at the typical heights that can be seamlessly bound to fit any area. The interlocking edges help here. The board facers stick easily to all adhesives commonly used in construction, including PVC and foil tape for securing bonds or exposed cavities.

Polyiso is a versatile insulator, used mainly for roofing, like the Kingspan TP10 mentioned above, but also has decent moisture resistance making it good for insulating walls and floors. Variations in facer material which also include plywood or Oriented Strand Boards (OSB) are typically used in insulating walls and can serve as a nail base. All boards from all manufacturers sold on the UK market are designed and produced to current building standards for both residential and commercial uses relating to fire safety, thermal efficiency and environmental impact.

Installing Polyiso

Polyiso can be installed by the keen DIYer or best left to a professional. If you e going the second route, consider the labour costs, but also how much material is needed. In roofing projects, calculate the total area to be insulated and add another 10-15 per cent of additional board. Figure out the width and thermal value needed as this raises costs. Boards are attached to frames by countersink screws in a tight, snug fit. Any exposed areas over piping or joists are covered with tape.

Buying Rigid insulation

Rigid insulation is a relatively new form of roof, wall, and floor solution that is eco-friendly like using heat lamps in the bathroom, has optimal thermal properties, is largely flame retardant, resists moisture and also serves as an acoustic barrier. It is easily and quickly installed with minimal hassle. Look for rigid insulation from established producers in large hardware chains and stores selling insulation solutions.